JointCheck is an automatic inspection system which inspects safety splice-bars of rail connections at high speeds of more than 100 km/h. Safety-relevant errors such as missing bolts or crack formations are inspected and entered in a track state protocol as a result so that an objective status of the inspected track is provided to the user with a high quality and safety in the shortest period of time. With the help of state of the art image processing technologies, JointCheck ensures that the inspection of the connections becomes quicker, safer and more reliable.

Recording

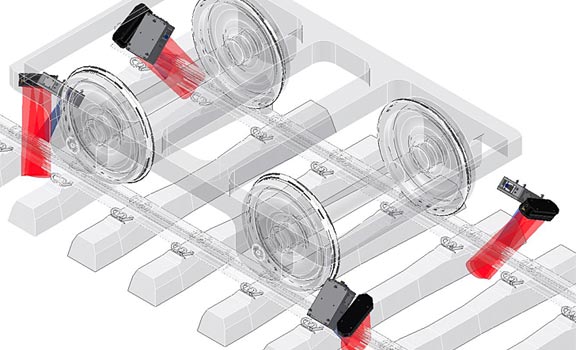

The picture recording system is integrated in device modules suitable for railway vehicles, which are installed in a carrier frame on the bogie frame of the carrier vehicle.

The camera systems arranged at both sides of the rail consist of monochrome digital line scan cameras and a highly coated lens with a fixed focal length.

The photograph is taken controlled along the optical path length by means of an incremental position encoder linked to the wheels and is independent of the speed. The fault pattern assignment to the current rail position is controlled by means of a central chainage system.

The inspection area is illuminated by powerful headlights. The illumination of the entire inspection area is arranged as a reflected-light illuminator for forming optimal contrast in dry and wet weather conditions.

Evaluation / Documentation

The resulting pictures are evaluated online by means of ultra-modern image processing algorithms. The fault patterns are classified automatically and the results are provided in a fault protocol immediately after inspecting the rails, archived in a database or forwarded to superordinated systems.

Résumé

The system includes the following features:

- Scalable speed of up to 130 km/h

- High detection performance

- Low incorrect detection rate

- Easy operation; intuitively controllable user interface

- Modular concept

- Low maintenance costs

- Proven suitability for railway vehicles

- Easy integration thanks to small space requirements both under and in the vehicle

- Open system; easy adaption to country-specific database systems or central data acquisition on the vehicles

JointCheck

JointCheck