Sophisticated, fast and practical – every component used to make OPTIMAT C+ draws on the skills gained from many years of experience with optical inspection systems.

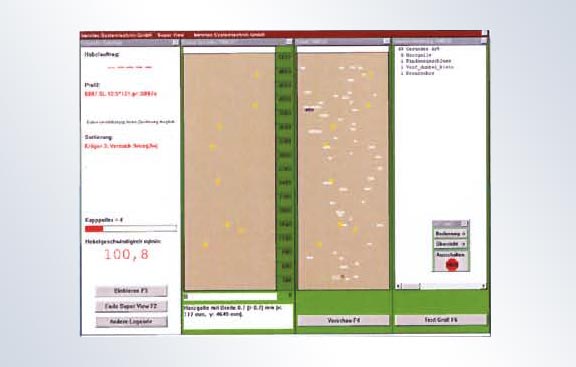

Intelligent computing processes for analysing and detecting flaws are to be found at the heart of the software. OPTIMAT C+ is operated with mouse and keyboard using a clearly structured Windows-based user interface. All software modules are network capable and can be easily integrated into existing system landscapes.

The basic version includes freely definable sorting classes as well as functions for setting error tolerances and generating statistics about qualities. The SuperView tool, which presents inspection data graphically on the screen, is also included in the scope of delivery.

The optional BDE interface that is always adapted individually to the partner system is responsible for ensuring the seamless integration of the quality data into any company-specific data system.

Modules for expanding the software for the OPTIMAT C+ depending on requirements are also available: The ‘extended statistics package’, for instance, permits detailed analyses that are able, for example, to facilitate the early detection of tool defects. The ‘simulation’ option uses actual inspection data to show how different settings will affect the sorting decision. Customer-specific software adaptations and upgrades are also possible at any time.

Optimat Software

Optimat Software